Electrical Machines and Power Electronics

The Electrical and Electronic Power Engineering Group is actively engaged in research into power electronic systems, novel electrical machines, and drives. There is a blend of interests and skills amongst the academic and research staff, providing a rare multidisciplinary strength to the Group; including expertise in very high voltage and current, novel magnetic design and power systems. The aim of the research is to make significant contributions to the understanding and development of power electronics, machines and derived systems.

Centre for Advanced Electronically Controlled Machines and Drives

Recent work in the field of electrical machines has lead to the development of a new type of electric motor that is energy efficient, electronically controlled and of a low cost to manufacture, with the intention to make OEM manufacturers aware of an alternative to the world’s reliance on inefficient single phase induction motors. These energy efficient motors are based on new patented designs and are essentially permanent magnet based brushless DC motors with very low electronic component count. The new designs have been developed for low torque ripple and quiet operation. The new motors are attracting growing commercial interest worldwide.

Traditionally Dr. Lefley has developed electric motors for electric and hybrid vehicles. However, recently has also developed new bespoke motor/generator technologies for aerospace applications where high power densities at very high speeds are essential. Such machines are designed for directly coupled gas-turbine applications, where a combined high speed starter coupled with a generator capability is required. This is a new field and is of considerable interest not only in aerospace but in military applications as well. Further work on energy efficient motors for industrial fan and pump applications is also on-going and is currently being spun-out through Synchropulse Ltd (see below). Dr. Lefley has developed in conjunction with colleagues from the Electrical and Electronic Power Engineering Group a complete fuel cell based electric vehicle drive system using a Nexa fuel cell, ultra-capacitors for energy storage, and an energy efficient permanent magnet brushless DC motor.

Power Electronics and Pulsed Power

Dr. Lefley has had considerable experience in development of power electronic based systems including recently, the application of pulsed power both at very high currents and high voltages.

The work on ultra-rapid battery recharging stemmed from fundamental work on how a rechargeable battery may accept charge at a high rate without causing deleterious effects to the battery such as overheating, gassing, active material shedding, etc. The purpose of this research was to investigate and develop new ways of rapidly recharging batteries by taking into account the electrochemistry and physical effects of rapid recharging on the battery. The Group has had considerable success in developing a new ultra-fast charging technique using pulsed power electronics to enable lead-acid batteries to be rapidly charged without overcharging, excessive gassing, or overheating. A real-time electronic charge management system prevents overcharging by controlling the rate at which the charge pulses are injected. This system substantially reduces gassing until a level of almost 90% state of charge is reached. A 24 kW charger has been developed to rapidly recharge large battery installations of between 24 to 72 volts at 800 Ahr capacities in under an hour.

The very high current power electronics (up to 2,500 amps) is applicable to all large scale energy storage media, and interested parties are encouraged to contact Dr. Lefley. Much of the ultra-rapid battery recharging work is currently seeing commercial interest. The work on electrostatic precipitation was an application of modern high frequency switched mode power electronics to replace the traditional low frequency transformer/rectifier set, but also to improve the dust collection efficiency in the precipitator by applying a controllable pulsed waveform from the new power supply. This system was implemented in a pilot project at Didcot B power station in Oxfordshire, UK.

Recent Publications:

• Optimal Design of a Novel Single Phase PM BLDC Motor Using Genetic Algorithm, Lefley P, Ahmed S, EPE-PEMC 2012, Novi-Sad, September 2012.

• Cogging Torque Minimization in the Double Stator Cup Rotor Machine, Diryak E, Lefley P, 4th Symposium on Applied Electromagnetics SAEM'12, 3rd to 6th June 2012, Sopron Hungary.

• High Voltage, High Frequency Transformer Design, Lefley P, Devine P. Transformers Analysis Design and Measurement, CRC Press, Monograph Ch 21, ISBN 9781466508248.

• Synthesis and Analysis of a High-performance Low-cost Permanent Magnet Brushless DC Motor, Lefley P, International journal for Computation and Mathematics in Electrical and Electronic Engineering (COMPEL).

• Fault Detection of a Series Compensated Line during the Damping Process of Inter-area Mode of Oscillation, Lami F, Lefley P. IET DPSP 2012 - Protecting the Smart Grid. The 11th International Conference on Developments in Power System Protection. 23-26 April 2012.

• Rechargeable batteries – Part 4: Battery graveyard, Energize April 2012 Lefley P, Soge A, Starkey J

• Rechargeable batteries – Part 3: Lithium-ion batteries, Energize April 2012 Lefley P, Soge A, Starkey J

• Rechargeable Batteries Part 2: Nickel based batteries, Energize March 2012 Lefley P, Soge A, Starkey J

• Rechargeable Batteries – The Evolution and Beyond, Energize Jan/Feb 2012 Lefley P, Soge A, Starkey J

• A New Design of Low Cost Energy Efficient Single Phase Brushless DC Motor, Lefley P, Ahmed S, Journal of Electrical Research Review, ISSN 0033-2097, 2/2012.

• Static Characteristics of a Novel Low Cost Brushless DC Permanent Magnet Motor, Lefley P, Journal of Electrical Research Review, ISSN 0033-2097, R88 NR 1a/2012.

• A Novel Three-Phase Buck-Boost Power Quality Converter, Lefley P, Starkey J, Seventh Mako/CIGRE Conference October 2 – 4, 2011.

• Synthesis and Analysis of a High Performance Low-Cost Permanent Magnet Brushless DC Motor L. Petkovska, P. Lefley, G. Cvetkovski XV International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering – ISEF'2011 Funchal, Madeira September 2011.

• Optimisation of the Design Parameters of an Asymmetric Brushless DC Motor for Cogging Torque Minimisation, Lefley P, Petkovska L, Cvetkovski G, European Power Electronics Conference EPE 2011, Birmingham, September 2011.

• From Dynamic Modelling to Experimentation of an Induction Motor Powered by a Doubly-Fed Induction Generator by Passivity based Control, Electrical Machines and Drives, InTech, Monograph Ch 7, ISBN 978-953-307-548-8.

• Design and Control of the Brushless Doubly Fed Twin Induction Generator (BDFTIG) - Part 2, Bensadeq A, Lefley P, IEEE 14th International Power Electronics and Motion Control Conference 6th to 8th September 2010, (EPE-PEMC 2010), Ohrid.

• Finite Element Analysis of a Novel Single Phase Permanent Magnet Brushless DC Motor, Lefley P, Ahmed S, IEEE 14th International Power Electronics and Motion Control Conference 6th to 8th September 2010, (EPE-PEMC 2010), Ohrid.

• Study of the Impact of Asymmetrical Stator Pole Arc on the Cogging Torque for Single Phase Permanent Magnet BLDC Motor, Ahmed S, Lefley P, IEEE International Conference on Electric Power and Energy Conversion Systems 10th to 12th November 2009, (EPECS09), Al Sharjah.

• Design and Control of the Brushless Doubly Fed Twin Induction Generator (BDFTIG), Bensadeq A, Lefley P, IEEE 11th Spanish Portuguese Conference on Electrical Engineering 1st to 4th July 2009, (11CHLIE), Zaragoza.

• Development of a Single Phase PM BLDC Motor from a Novel Generic Model, Ahmed S, Lefley P, IEEE 11th Spanish Portuguese Conference on Electrical Engineering 1st to 4th July 2009, (11CHLIE), Zaragoza.

• Energy Efficiency Advantages of a Brushless DC Motor for a Variable Speed Compressor. Lefley P , Currington I, International Rotating Equipment Conference, Dusseldorf, 27th to 29th October 2008.

The Group is proud to be accommodated in a large laboratory suite (comprising of three dedicated laboratories) that has recently seen a £1M refurbishment. There are a wide range of laboratory resources and specialist equipment including; a 400 kV test facility, a 3000 amp pulsed power generator, a large battery charge/discharge unit designed for fork-lift truck and submarine batteries, a large scale wind turbine simulator, a 40 kW solar panel installation, a range of electrical machine test facilities up to 100 kW, including a high speed turbo-generator, magnetic and electrostatic modelling and CAD facilities. In support of the battery recharging work, the Group has access to our in-house electron-microscopy suite.

High Powered and Ultra-fast Battery Recharging

The purpose of this research is to investigate and develop new ways of rapidly recharging batteries by taking into account the electrochemistry and physical effects of rapid recharging on the battery. The Group has had considerable success in developing a new ultra-fast charging technique using pulsed power electronics to enable batteries to be rapidly charged without overcharging, excessive gassing, or overheating. A real-time electronic charge management system prevents overcharging by controlling the rate at which the charge pulses are injected. This system substantially reduces gassing of an aqueous electrolyte battery until a level of almost 90% state of charge is reached. A 24 kW charger (See picture) has been developed to rapidly recharge large battery installations of between 24 to 72 volts at 800 Ahr capacities in under an hour. This work has been a useful foundation for on-going research into the ultra-rapid recharging of lithium batteries used in various transport applications.

Electrostatic Precipitation

The Electrical Power Group has a long history in electrostatic precipitation, primarily for cleaning up flue gas emissions from power stations. This research work includes the improvement in the design of the precipitator and the high voltage electrodes for greater dust collection efficiency by using electrostatic field modelling. The other area of research where the Department has made a significant impact in this industry is in the creation of a new high voltage, high power, power supply.

The conventional 50/60 Hz transformer/rectifier power supply design became the standard issue due to a lack of topological progress since their initial introduction by Frederick Cottrell in the early 1900s. However, this kind of unit has severe drawbacks as far as operation is concerned, including, but not limited to:

Low quality input currents and low power factor

Sluggish operating characteristics

Low power supply efficiency

Large size, weight and civil engineering costs associated with the oil insulated transformer.

The research work within the Group ultimately provided a step change in technology for the industry, by implementing a modern switched mode power supply topology to achieve a major improvement in the efficiency and effectiveness of electrostatic precipitators. The research prototype overcame design difficulties encountered with combining high frequency, high voltage and high power in a single power supply. It also served as a research tool to identify the usefulness of applying a variable waveform – including the addition of microsecond high voltage pulses – to the electrostatic precipitator for improved dust collection efficiency. In order to fulfil this technological achievement, a very special high voltage power transformer needed to be designed; one that could withstand very high voltages (up to 100 kV), operate at high frequencies (20 kHz) and at high power (up to 70kVA), had low leakage reactance for fast response times, was capable of withstanding short circuits, and was greater than 90% efficient.

The high frequency approach has numerous advantages over the traditional mains frequency rectification equipment in that, with a switching period of 100 microseconds compared with 8 or 10 milliseconds the output waveform approaches pure DC and the recovery time following a flashover is considerably reduced. This enables the precipitator to operate at a much higher (average) voltage and hence performance, since the dust collection efficiency of any precipitator is proportional to the square of the operating voltage. In addition, electrical safety is increased because when the precipitators arc and spark the arc is extinguished much more rapidly than with the conventional 50/60 Hz transformer/rectifier unit.

As part of the fundamental research work, methods of controlling the high voltage field in order to increase the dust collection efficiency were implemented. This included the injection of variable shaped voltage wave forms onto the high voltage field, not possible with a standard 50 Hz unit. Leicester’s prototype 70 kVA switched mode power supply was built, installed, and trialled at Didcot (A) power station in 1998. Since this pioneering research work at Leicester, switch mode power supply units are being installed all over the world today.

Electrical Insulation and Dielectric Phenomena

The “High Voltage Lab” encompasses a diversity of activity following the theme of Electrical Insulation and Dielectric Phenomena. We particularly welcome industrially-oriented research and consultancy.

Areas of work include:

1.Dielectric Spectroscopy:

Dielectric spectroscopy is a powerful technique, which we use:

as a diagnostic for electric ageing

to examine how electrical charge moves through dielectric systems

to characterise the dielectric properties of materials and insulating systems

We use a Solartron 1296A Dielectric Interface coupled to a frequency response analyser, and we have also developed high-voltage time domain techniques and ultra-sensitive bridge techniques for low-loss materials such as cross-linked polyethylene.

Measurements can be made:

over the frequency range 10-5 to 107 Hz

over the temperature range 0 to 250 deg. C (depending on the material)

over a range of humidities and voltages

at tan deltas as low as 10-5.

2.Nano-Dielectrics:

At Leicester we pioneered the first experimental work (reported in Nanotechnology) showing that insulation materials (e.g. polyethylene) filled with nanometric (e.g. 50nm diameter silica) particles have the potential to enhance dielectric properties properties significantly.

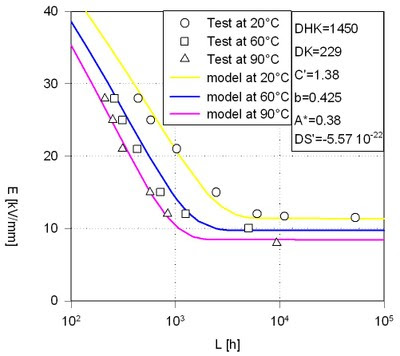

The graph shows how space charge accumulated in epoxy filled with both "micro-particles" and nano-particles" led to increased fields under high voltage DC conditions. The field, which may lead to enhanced ageing and breakdown, was much higher for conventional materials filled with micro-particles than those with nano-particles.

Advances in Understanding Electrical Breakdown in HV Insulation Systems:

We have led the way in understanding electrical degradation and breakdown of polymeric and composite insulators. For example, work, supported by the National Grid Company, has led to the development of novel physical models and computer simulations of electrical tree growth, an important electrical breakdown mechanism in polymeric insulation.

The high voltage laboratory activities include:

Experimental studies of electrical breakdown in a range of insulating materials and systems

The use of ultra-sensitive partial discharge (down to 10*10-15 C) and electroluminescence (single photon) techniques

Development of condition monitoring techniques for HV insulators

Forensic studies of insulator failure in cables, accessories, bushings, etc.

Theoretical understanding of electrical ageing leading to diagnosis and prognosis:

Leicester has played a prominent role in the development of quantitative physical models for electrical ageing. This can serve as a basis for the identification of ageing markers and the prediction of service life.

Models have been developed for

- Electrical treeing. The model quantitatively reproduces observations of treeing and accurately predicts both bush and branch-type treeing.

- Ageing due to the accumulation of space charge at defects. The models predicts characteristic life from generic features such as local ageing susceptibility and energy concentration. The model yields damage structures and relates failure statistics to local variations.

Space Charge Measurement:

Under high field conditions, particularly under DC, charge may be accumulate inside an insulating material. This can be detrimental as it increases and distorts the electric field, which may lead to premature ageing and failure.

The laboratory collaborated with Dr John Alison and Prof. Robert Hill at King's College London to develop a range of pusled-electro-acoustic measurement systems for measuring space charge distributions in films and slabs of solid insulation.

The apparatus has a resolution of around 1pC and 25 microns. Fast measurements can be made with one of the systems, allowing, for example, the observation of the movement of charge with time.

The graph shows charge moving in "packets" through a 0.15mm film cross-linked polyethylene under a field of 120kV/mm..

1 comment:

IQRA Technologies Ltd. was established in 2019 in Bangladesh. We are focused on wholesale and also on the retail business of FTTx products. Visit our Splicing Maching here

Post a Comment